The integration of 100G optical modules with smart diagnostic systems is increasingly vital in the realm of smart manufacturing. As industries evolve towards greater digitalization, the demand for high-speed data transmission and efficient diagnostics has risen dramatically. By 2025, we anticipate a landscape where seamless connectivity between machines, operators, and systems becomes the norm, enabling real-time feedback and proactive maintenance strategies.

Optical modules are at the heart of this transformation. These components facilitate the transmission of data over optical fibers, providing bandwidths that are essential for the rapid data flow required in smart manufacturing environments. The market for optical modules is thriving, driven by their capacity to support next-generation networks, such as 5G and IoT applications. According to research, the global optical modules market is projected to reach $30 billion by 2025, emphasizing a compound annual growth rate (CAGR) of 15% from 2022 onwards. This growth reflects the increasing reliance on optical communication technologies to meet rising data demands across various industries.

To better understand how optical modules function and their significance in manufacturing, consider the following table:

| Technology | Description | Applications |

|---|---|---|

| 100G QSFP28 | High-density optical transceiver supporting 100G Ethernet. | Data centers, high-performance computing. |

| 10G SFP+ | Standard transceiver for 10G Ethernet applications. | Enterprise networks, telecoms. |

| 400G FR4 | Advanced transceiver for high-bandwidth applications. | Cloud data centers, 5G networks. |

| CWDM (Coarse Wavelength Division Multiplexing) | Method to increase bandwidth over existing fiber infrastructure. | Metropolitan area networks. |

Diving deeper into the types of optical modules, the 100G optical modules are engineered for high data rates and are crucial for both intra- and inter-data center connectivity. They utilize advanced modulation formats to achieve impressive transmission distances, often exceeding 80 km without significant signal degradation. Technologies like DWDM (Dense Wavelength Division Multiplexing) enable the simultaneous transmission of multiple data streams across a single fiber, maximizing bandwidth utilization. Other module types, like SFP+ and QSFP28, provide scalability and flexibility, catering to diverse manufacturing needs.

In examining future applications, by 2025, we expect notable advancements in optical modules, particularly within smart manufacturing systems. For instance, optical modules integrated into smart factories can facilitate real-time diagnostics and predictive maintenance. Imagine a scenario where machinery equipped with 100G optical modules communicates vital performance data instantly. This connectivity allows managers to detect abnormalities before they escalate, minimizing downtime and enhancing productivity. Companies implementing such technology could see a reduction in maintenance costs by 20% and improved operational efficiency.

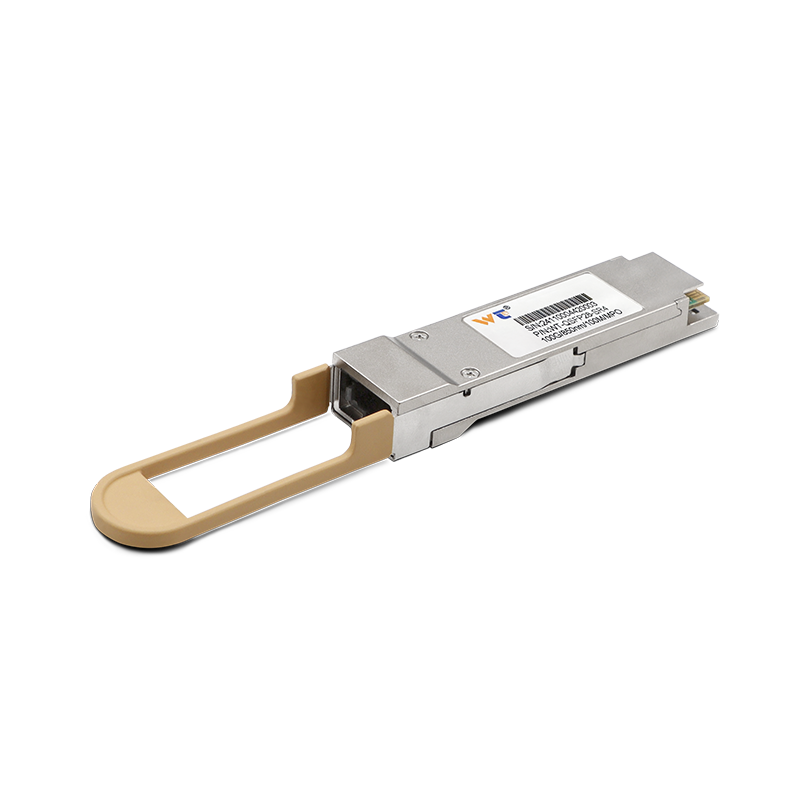

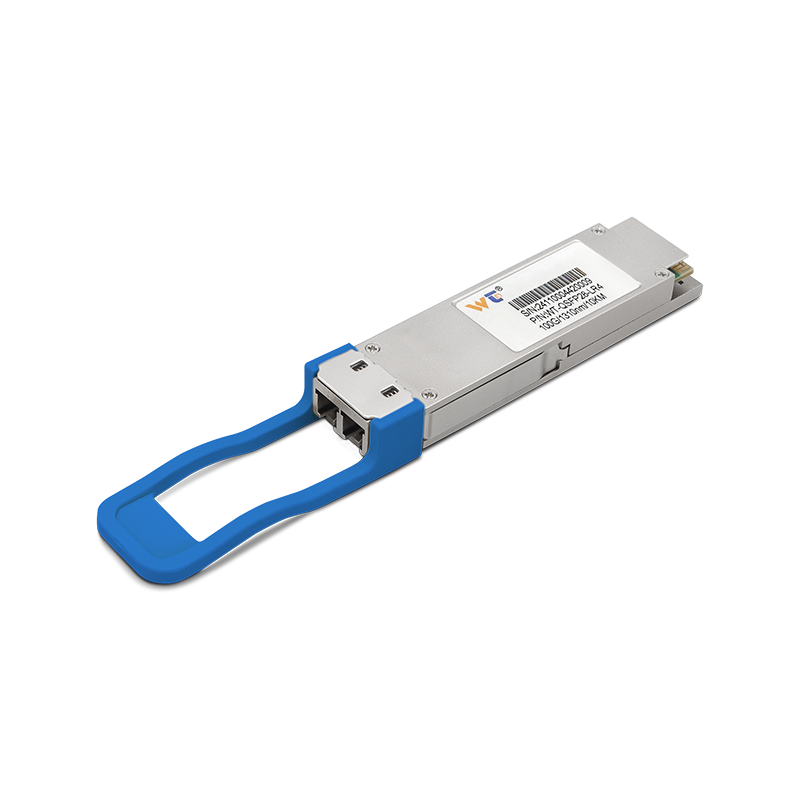

Our website offers a comprehensive range of optical module products, each subjected to rigorous quality testing to excel in various operational environments. Whether you require solutions for high-speed data transmission or long-distance communication, our optical modules are designed to meet your specific requirements. With speeds reaching 100G, they ensure robust performance that is essential in today’s competitive manufacturing landscape.

In conclusion, the integration of 100G optical modules with smart diagnostic systems represents a pivotal shift in smart manufacturing. As we progress towards 2025, the demand for high-bandwidth, reliable communications will only intensify. By leveraging advanced optical technologies, manufacturers can enhance their operational efficiencies, enabling a future that is both innovative and resilient. Embracing these technologies today paves the way for a more connected and intelligent manufacturing ecosystem.