In the rapidly evolving landscape of smart manufacturing, the integration of 100G optical modules with advanced diagnostic systems is set to become a game-changer by 2025. This relationship not only addresses the growing demand for seamless data transmission but also enhances the operational efficiency of manufacturing processes. As global industries pivot towards digitization and automation, the reliance on high-speed connectivity will only intensify, driving innovation and adaptability at an unprecedented scale.

Recent advancements in optical module technology indicate a significant shift toward robust and versatile solutions. These modules ensure high data rates, with a focus on minimizing latency and maximizing bandwidth. In smart manufacturing, where real-time data processing is critical, 100G optical modules facilitate lightning-fast communication between devices and systems. This capability supports a multitude of applications, including real-time monitoring, predictive maintenance, and automated control systems. Industry experts predict a compounded annual growth rate (CAGR) of over 15% for optical module market segments, primarily driven by such applications.

Technical Overview of Optical Modules:

| Technology | Description | Application |

|---|---|---|

| Silicon Photonics | Integrates optical components at a micro-scale. | High-speed data centers. |

| CWDM/DWDM | Wavelength multiplexing technologies enabling increased capacity. | Long-distance communications. |

| Active/Passive Optical | Different performance components for various requirements. | Flexible manufacturing setups. |

The primary types of optical modules applicable in smart manufacturing environments are distinguished by their ability to cater to specific operational needs. Silicon Photonics modules leverage miniaturization, leading to enhanced speed and efficiency. They are vital for data centers that require rapid processing and minimal power consumption.

Coarse Wavelength Division Multiplexing (CWDM) and Dense Wavelength Division Multiplexing (DWDM) stand out by allowing multiple data streams to coexist on a single optical fiber. This characteristic is crucial for long-distance communication, reducing the need for extensive cabling infrastructure, thereby cutting costs and improving reliability.

As we approach 2025, case studies demonstrate that advanced optical modules are integral to creating highly responsive network architectures. For instance, in an automated factory setup, the deployment of 100G modules provides the bandwidth necessary to connect machines, sensors, and control systems in real time. This interconnectedness leads to optimized workflows, reducing downtime and increasing production rates. Companies are harnessing these technologies not only for efficiency but also for smoothing their transitions into Industry 4.0 paradigms.

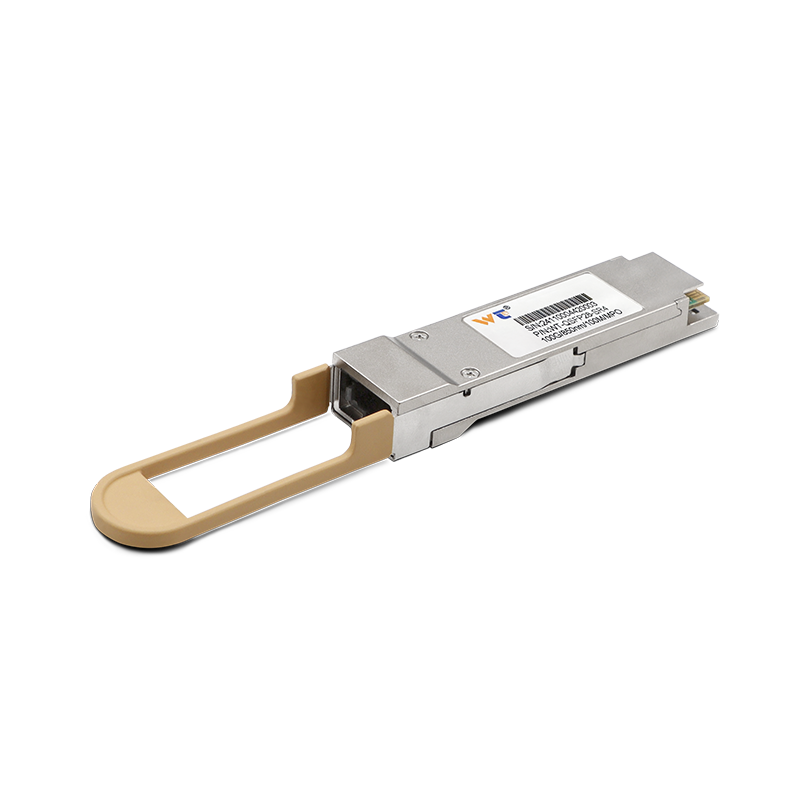

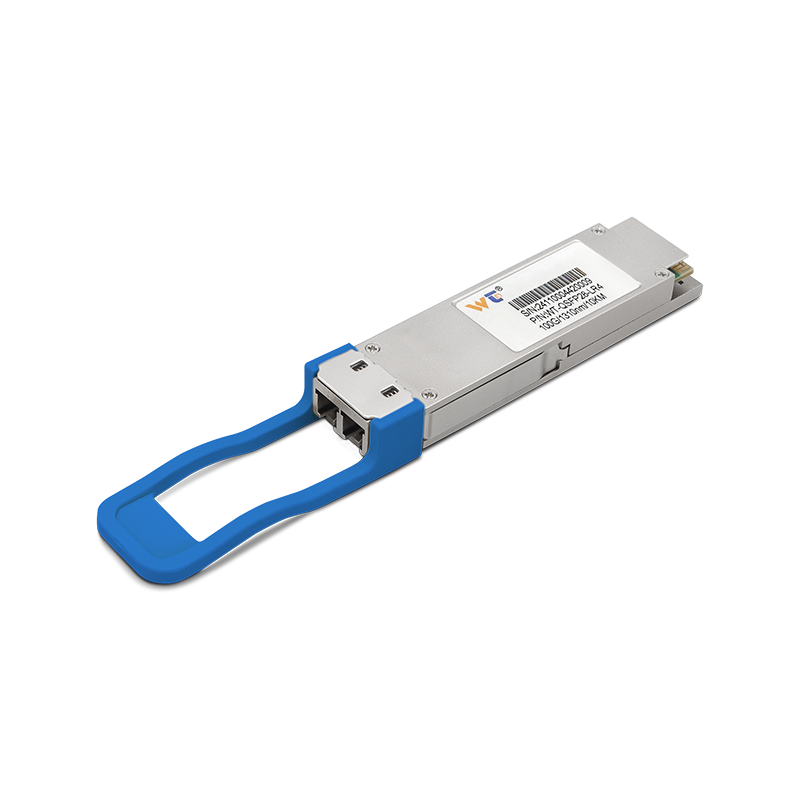

At our website, we proudly offer a range of 100G optical module products that have undergone rigorous quality testing. We ensure that our modules perform exceptionally across various applications, empowering businesses to meet their operational demands. Whether it’s for high-speed data transmission or long-distance communication, our optical modules are designed to deliver consistent, reliable performance. With our products, you can trust that you are investing in the future of smart manufacturing.

In summary, the integration of 100G optical modules with smart diagnostic systems is poised to redefine smart manufacturing by 2025. The evolving landscape emphasizes the critical role these technologies play in facilitating rapid communication and efficiency. As industries embrace these advancements, they will not only enhance their operations but also pave the way for innovations that support sustained growth and competitiveness in a digital era.