The field of smart manufacturing is rapidly evolving, with increasing reliance on advanced technologies to enhance production efficiency and safety. In this context, real-time warning applications of 100G optical modules play a pivotal role. By 2025, the demand for fast, reliable communication in manufacturing environments will surge as industries adopt more automated systems to maintain competitiveness.

In recent years, optical modules have become essential components in modern communication systems. These modules, particularly 100G optical modules, are engineered to support high-speed data transmission over fiber optic networks. The integration of optical modules into smart manufacturing environments facilitates improved data flow, enabling better monitoring and control of production processes. The industry trend indicates a steady growth in the demand for these modules, driven by the increasing complexity of manufacturing systems and the necessity for real-time data analysis. As technology progresses, the market is also seeing a shift toward more sophisticated optical solutions, which can address the increasing need for higher bandwidth and low latency.

| Optical Module Technology | Key Functions |

|---|---|

| 100G Transceivers | High-speed data transmission |

| Single-mode and Multimode | Flexibility in application |

| Bi-directional modules | Reduced fiber utilization |

| Coherent optics | Enhanced long-distance communication |

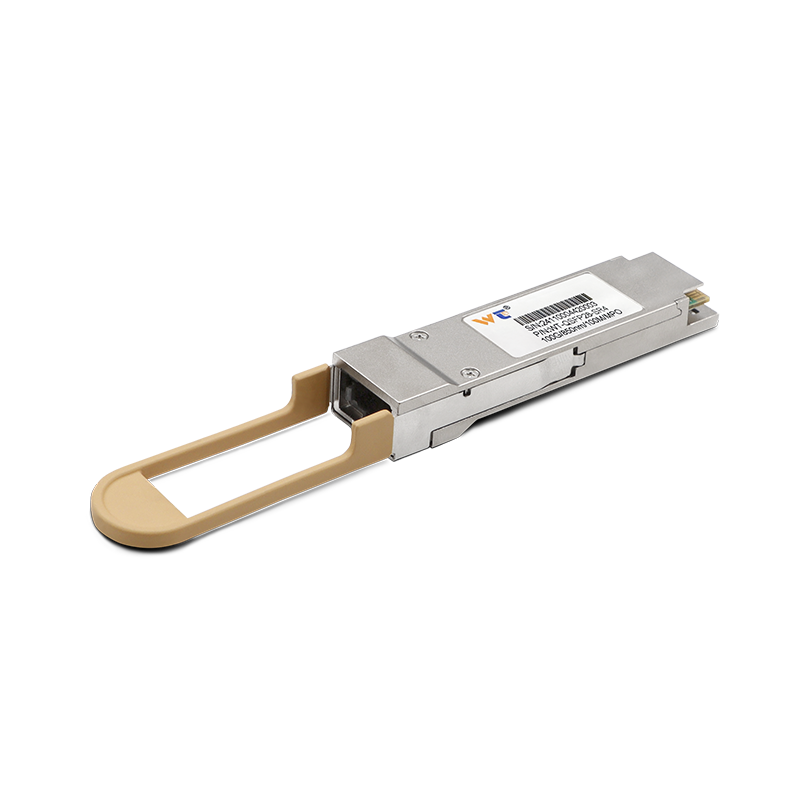

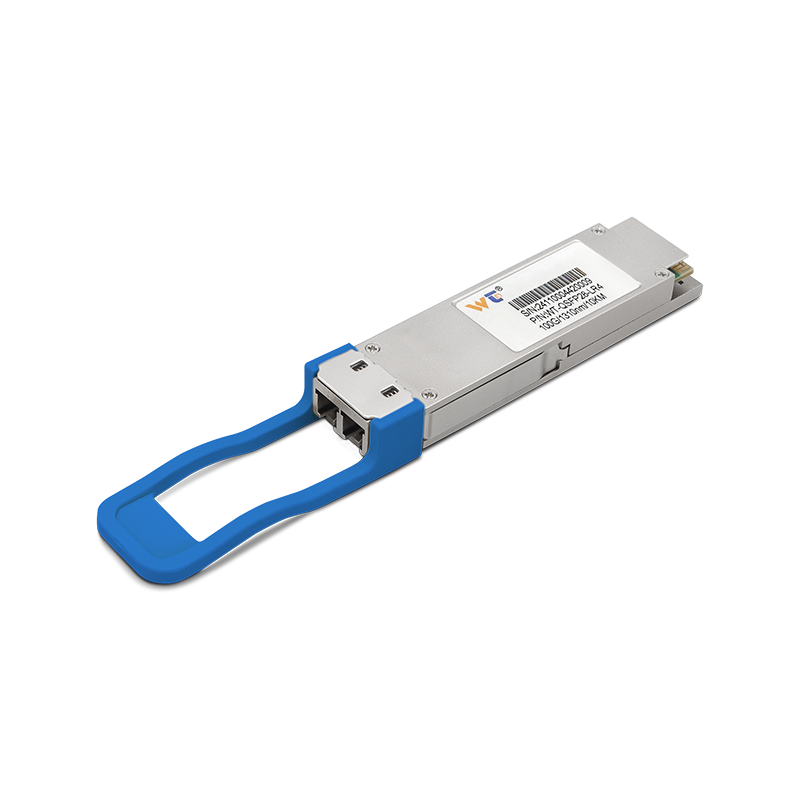

The types of optical modules that are reshaping smart manufacturing are diverse. 100G transceivers are a cornerstone technology offering high-speed data transfer suitable for the growing demands of data-intensive applications. Alongside these, single-mode and multimode optical modules cater to various networking scenarios, enhancing flexibility and performance deployment. Furthermore, bi-directional modules provide the advantage of utilizing a single fiber for simultaneous data transmission and reception, significantly optimizing fiber resource utilization. Coherent optics further elevate these capabilities, providing reliable communication over long distances, thus supporting geographically dispersed manufacturing units in maintaining connectivity.

As we look ahead to 2025, network topology in smart manufacturing will likely leverage optical modules to create integrated communication ecosystems. Case studies indicate that the use of 100G optical modules enables seamless intercommunication among machines, sensors, and data analytics platforms. For instance, a factory employing this technology can instantly relay warnings about equipment malfunctions, ensuring minimal downtime. This rapid communication not only enhances operational efficiency but also improves safety, as potential hazards can be identified and addressed in real time.

Our website offers a comprehensive range of optical module products that have undergone rigorous quality testing to ensure exceptional performance in various application scenarios. Whether your need is for high-speed data transmission or long-distance communication, we guarantee that our optical modules will meet your expectations and elevate your manufacturing capabilities.

In conclusion, the integration of 100G optical modules in smart manufacturing environments is not just a trend; it is a necessity driven by the increasing complexity and demands of the industry. As the market evolves, these technologies will play a critical role in shaping the future of manufacturing, ensuring that real-time data flow and effective communication are at the forefront of production processes.