The landscape of smart manufacturing is evolving rapidly, driven by advancements in technology and increasing industrial demands. By 2025, the need for seamless integration of 100G optical modules with intelligent monitoring systems will redefine efficiency standards. This integration promises not only enhanced data transmission speeds but also improved system reliability, fundamentally changing how manufacturing operates.

In recent years, the market for optical modules has experienced significant growth. The demand for high-capacity data transfer in smart manufacturing applications is pushing the limits of current technologies. As we approach 2025, industries are increasingly adopting 100G optical modules, recognizing their role in facilitating real-time data analytics and automation. These modules support applications that require high-speed connectivity and minimal latency, essential for responsive manufacturing systems. Furthermore, as global competition intensifies, businesses are motivated to implement cutting-edge solutions that enhance productivity, safety, and overall operational efficiency.

| Feature | Description |

|---|---|

| Transmission Rate | 100 Gbps |

| Fiber Type | Single-mode and multi-mode fibers |

| Application Areas | Data centers, industrial automation, IoT |

| Benefits | High bandwidth, low latency, robust performance |

| Monitoring Capabilities | Supports real-time diagnostics and analytics |

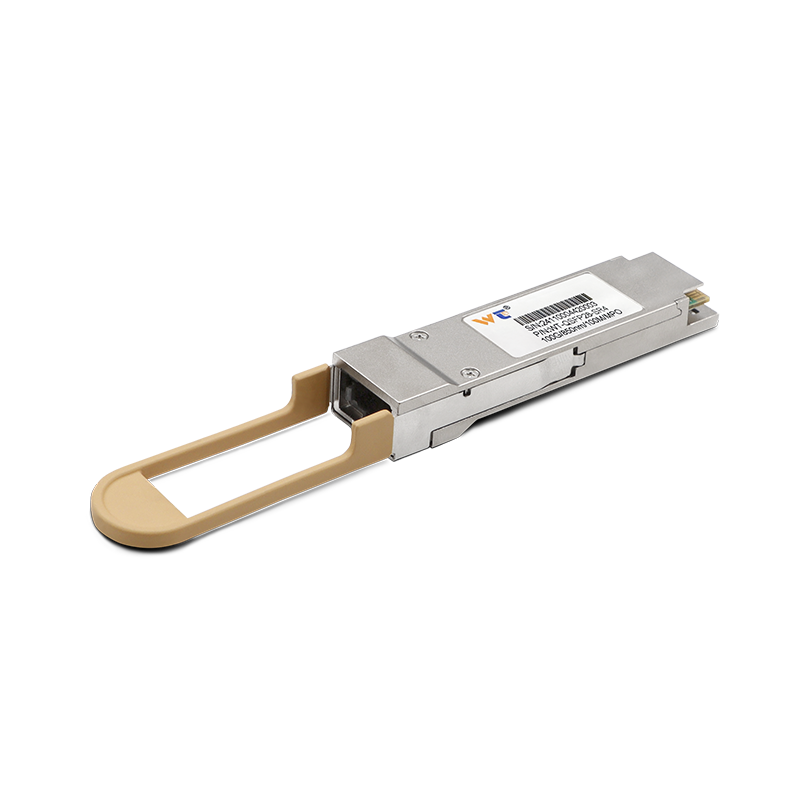

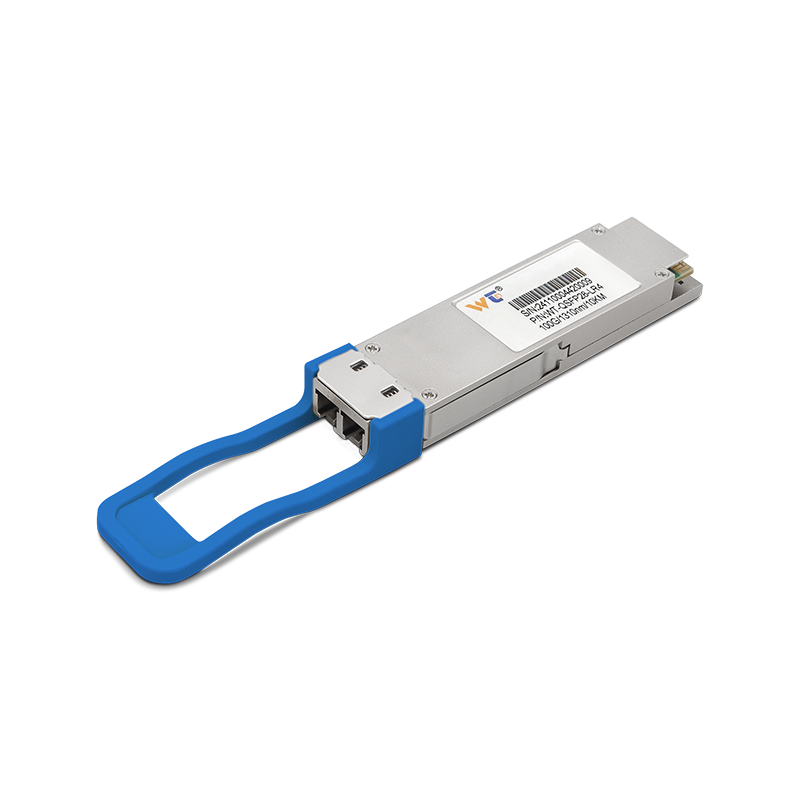

The types of 100G optical modules encompass a variety of technologies designed to meet diverse industrial needs. SFP28 (Small Form-factor Pluggable 28) modules are commonly used for short-range communications within data centers. Meanwhile, QSFP28 (Quad Small Form-factor Pluggable 28) modules enable higher data transfer capabilities, delivering up to 100 Gbps bandwidth, making them suitable for applications requiring vast data throughput. DWDM (Dense Wavelength Division Multiplexing) technology allows multiple signals over a single optical fiber, maximizing resource utilization in smart factories. The focus is not only on speed but also on versatility and scalability, critical for adapting to the dynamic requirements of modern manufacturing environments.

Looking ahead, the implementation of 100G optical modules in smart manufacturing networks will exemplify innovative use cases by 2025. For instance, integrating these modules with smart monitoring systems will enable manufacturers to facilitate continuous health checks of their equipment. Imagine a manufacturing plant where machines communicate via real-time data streams, utilizing 100G optical technology to ensure operational stability. This setup can significantly enhance predictive maintenance capabilities, reducing downtime and optimizing production efficiency. Additionally, cloud-based monitoring platforms can analyze incoming data, providing insights that lead to proactive decision-making and immediate responses to operational anomalies.

When it comes to performance, our available optical module products undergo rigorous quality assessment procedures, ensuring that they excel across a wide range of applications. In environments where high-speed data transmission is critical, our 100G optical modules guarantee the necessary bandwidth and reliability. These solutions are meticulously designed to support long-distance communications, enabling seamless integration with current industrial setups. You can trust that our products are engineered to meet the rigorous demands of diverse operational scenarios.

In conclusion, as we move towards 2025, the synergy between 100G optical modules and smart monitoring systems will transform the manufacturing sector. By enhancing connectivity and operational efficiencies, these technologies will empower businesses to meet emerging challenges head-on. It’s an exciting time for the industry, where the combination of speed, reliability, and smart technology will pave the way for a new era of manufacturing.