The world of optical modules is rapidly evolving, particularly with the advent of smart manufacturing techniques. As we approach 2025, the demand for high-capacity, real-time data transfer solutions will dramatically increase. Industries are pushing for efficiencies, seamlessly integrating 100G optical modules to optimize their processes, reduce waste, and enhance connectivity.

Optical modules play a critical role in modern communication networks. They are responsible for converting electrical signals into optical signals and vice versa, facilitating high-speed data transfer over vast distances. The industry trend is leaning towards more advanced multi-rate modules that support a variety of protocols while maintaining compact designs. As demand for bandwidth continues to skyrocket, the market for optical modules is projected to grow significantly, driven by the need for efficient data centers, cloud services, and 5G deployments.

| Optical Module Technology | Functionality |

|---|---|

| Transceivers | Convert data for transmission and reception. |

| DSP (Digital Signal Processing) | Enhance signal quality, enabling longer distances. |

| Wavelength Division Multiplexing (WDM) | Increase bandwidth using multiple signals at different wavelengths. |

| Optical Amplifiers | Boost signal strength without converting to electrical form. |

| Fiber Optics | Provide the medium for high-speed data transfer. |

There are various types of optical module technologies that contribute to the 100G landscape. Dual-rate transceivers are being introduced, allowing for flexibility in applications. Pluggable optical modules are gaining traction due to ease of installation and maintenance, facilitating upgrades without extensive infrastructure changes. Incorporating WDM technology helps maximize bandwidth utilization, as multiple data streams can be sent simultaneously on different wavelengths. Lastly, improvements in digital signal processing are vital for minimizing errors and improving overall signal integrity, providing a reliable foundation for smart manufacturing systems.

As we approach 2025, use cases of optical modules in smart manufacturing are becoming clearer. Scenario-based networking is emerging, where optical modules not only connect machinery but also communicate in real-time across integrated production lines. For instance, a factory can employ a series of optical links that allow machinery to share data instantly, significantly reducing lag and optimizing workflow. This interconnectedness is essential for predictive maintenance, where sensors relay information about equipment status, potentially reducing downtime and ensuring smoother operations.

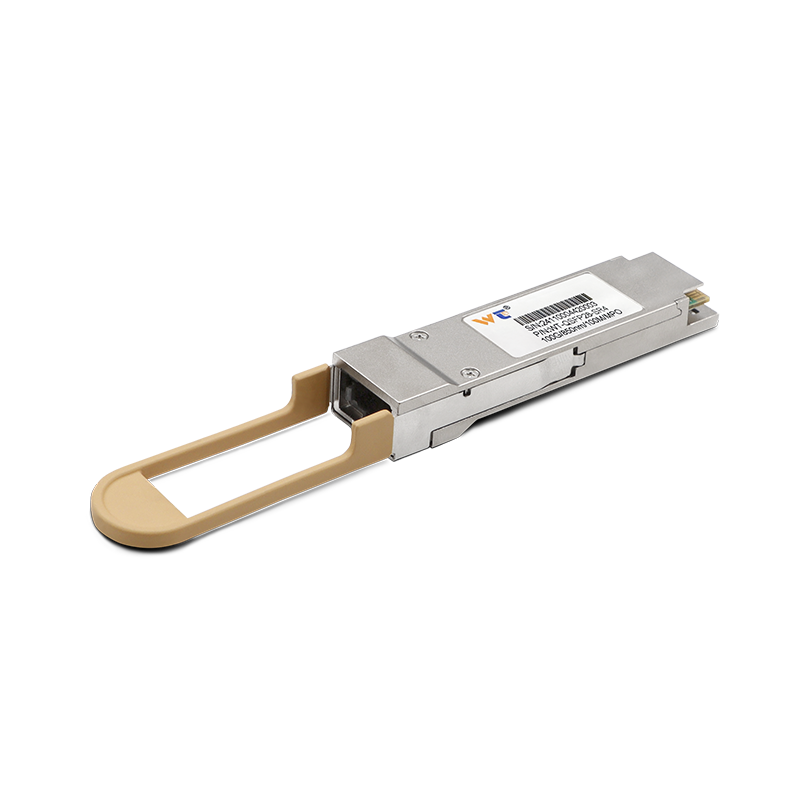

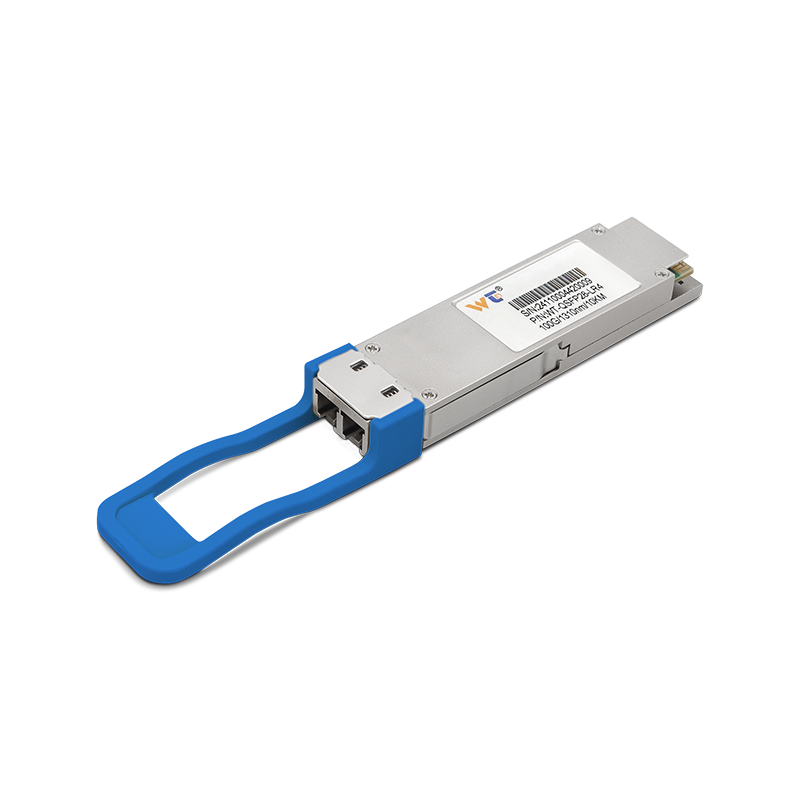

At our website, we offer a range of optical module products that undergo rigorous quality testing. This ensures that they perform exceptionally across various applications, from high-speed data transmission to long-distance communication. We understand the critical nature of reliability in smart manufacturing, which is why our optical modules are engineered to meet your diverse needs. Whether you are enhancing connectivity within a data center or developing an innovative smart factory, our solutions are designed to guarantee high performance and operational efficiency.

In summary, the journey towards 100G optical modules in the context of smart manufacturing showcases a promising future. As applications become more interconnected and complex, the role of optical modules will only grow in importance. The technology is not just about speed; it’s about resilience, reliability, and the ability to adapt to new challenges. Embracing these innovations today will pave the way for a smarter, more efficient tomorrow.