The rapid evolution of technology in the smart manufacturing industry has created a substantial demand for advanced optical modules. In 2025, the focus will increasingly be on high stability design, specifically for 100G optical modules, as industries leverage real-time processing and analyze vast amounts of data. The connectivity needs for IoT devices, automation equipment, and data centers will require robust and reliable optical communication solutions to enhance overall operational efficiency.

Optical modules are integral components in network systems, responsible for the conversion of electrical signals into optical signals and vice versa. The market for these devices is projected to grow significantly, driven by the surge in data traffic. A prominent trend is the demand for modules that support higher bandwidth and lower latency, essential for applications such as real-time monitoring, predictive maintenance, and AI integration. Increased investment in infrastructure will facilitate the deployment of high-speed networks, making optical modules vital for successful smart manufacturing strategies.

| Optical Module Technology | Function and Impact |

|---|---|

| Transceivers | Enable bidirectional data communication over fiber optic cables, increasing data transmission rates. |

| Wavelength Division Multiplexing (WDM) | Allows multiple signals to be transmitted simultaneously over a single fiber, optimizing bandwidth utilization. |

| Coherent Optical Technology | Enhances long-distance data transmission by using phase modulation, reducing signal loss and improving performance. |

| Optical Amplifiers | Boosts the signal strength in long-haul communications, essential for maintaining signal integrity over distances. |

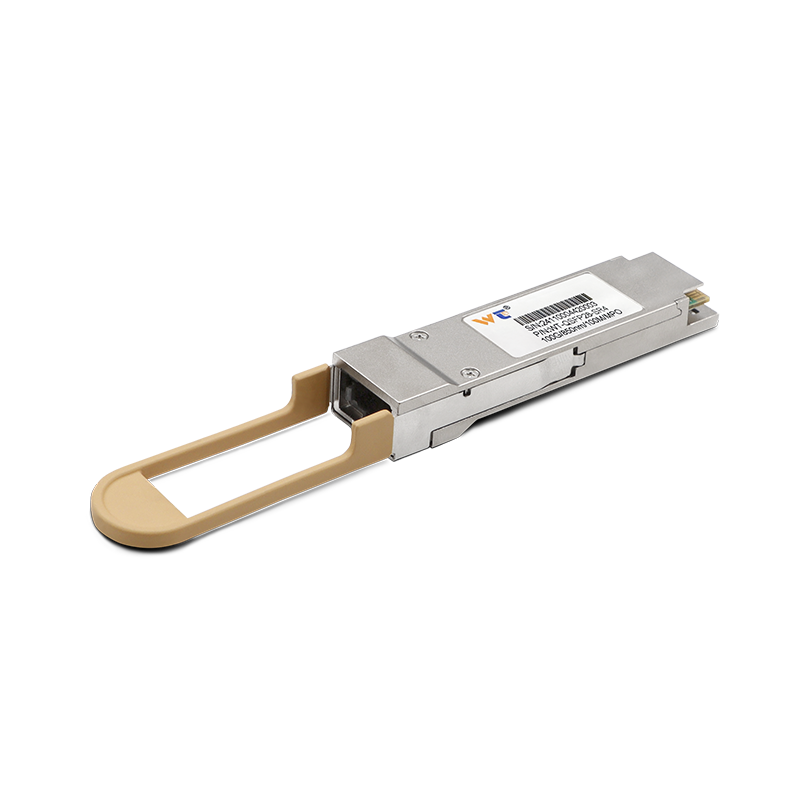

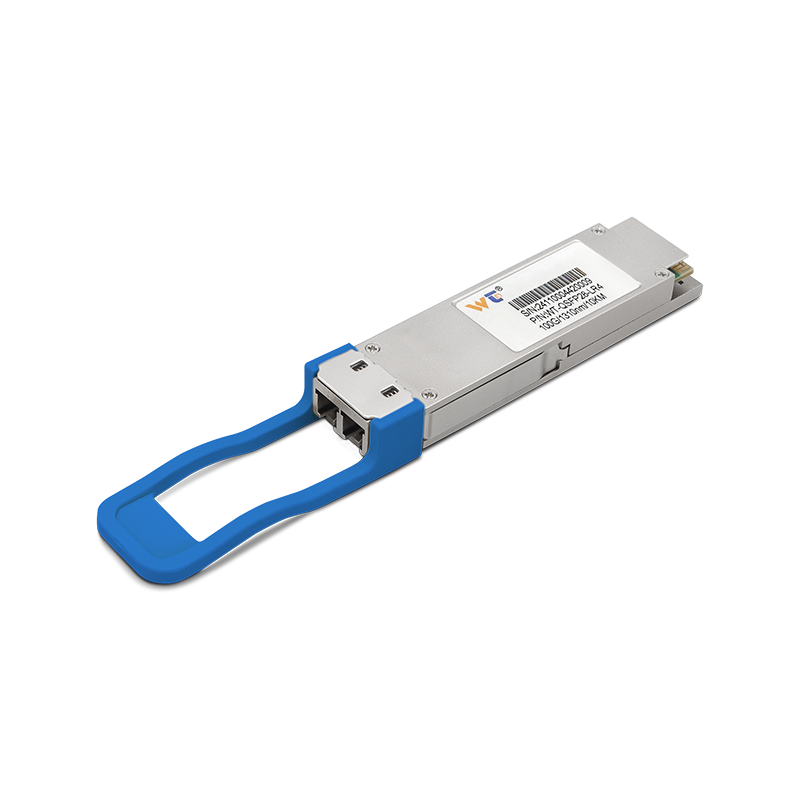

Various types of optical modules are becoming increasingly relevant in smart manufacturing scenarios. For instance, SFP+ and QSFP+ modules are popular choices due to their compact form factor and high bandwidth capabilities. These modules facilitate seamless data transfer between devices, essential for high-performance computing tasks. The proliferation of 100G technology further accelerates the need for robust installations that support demanding applications. As factories integrate machine-to-machine communications and smart sensors, the reliance on high stability optical modules becomes paramount.

By 2025, specific networking scenarios utilizing innovative optical modules will illustrate the transformation of smart manufacturing. Imagine a factory floor where machines communicate effortlessly, transmitting data in real-time over a high-capacity optical network. For example, a system using 100G optical modules for automation can reduce latency and improve response times, leading to more efficient production processes. The implementation of such networks will also allow for enhanced remote monitoring and diagnostics, paving the way for predictive maintenance strategies that can minimize downtime.

Our website offers a range of optical module products, thoroughly tested for quality assurance. Each module is designed to perform exceptionally across various applications, ensuring we meet the unique demands of our clients. Whether it is for high-speed data transmission or long-distance communication needs, our optical modules guarantee reliable performance, reinforcing your system's integrity. Precision-engineered and rigorously evaluated, our products stand out as a preferred choice in the evolving landscape of smart manufacturing.

In conclusion, as smart manufacturing continues to evolve toward increased connectivity and efficiency, the demand for high stability optical modules, especially those designed for 100G applications, will be more critical than ever. The integration of these technologies will drive innovation, ultimately leading to greater productivity and enhanced operational capabilities in manufacturing environments. By prioritizing quality and reliability, industries can harness the potential of these advancements, confidently moving forward into the future.