In the rapidly evolving field of smart manufacturing, high-concurrency communication optimization is paramount. By 2025, the demand for seamless connectivity and faster data transfer rates will continue to surge. The integration of 100G optical modules will be crucial in meeting these network demands, enabling real-time data processing and enhancing overall operational efficiency.

Optical modules serve as the backbone of modern communication systems. They are essential for converting electrical signals to optical signals and vice versa. As industries advance, the trend in optical modules is leaning towards higher bandwidth, lower latency, and greater energy efficiency. The market for these technologies is projected to grow significantly, with innovations focusing on miniaturization and enhanced functionality. Key players in the optical technology landscape are investing heavily in research and development to meet evolving user requirements, reflecting a shift towards more integrated and versatile solutions.

| Technology Features | Functionality |

|---|---|

| High Speed (100G) | Enables rapid data transmission in high-density environments |

| Low Latency | Facilitates near-instantaneous communication, essential for smart applications |

| Energy Efficiency | Reduces operational costs and promotes sustainability |

| Compatibility | Works seamlessly with existing infrastructure, ensuring easy integration |

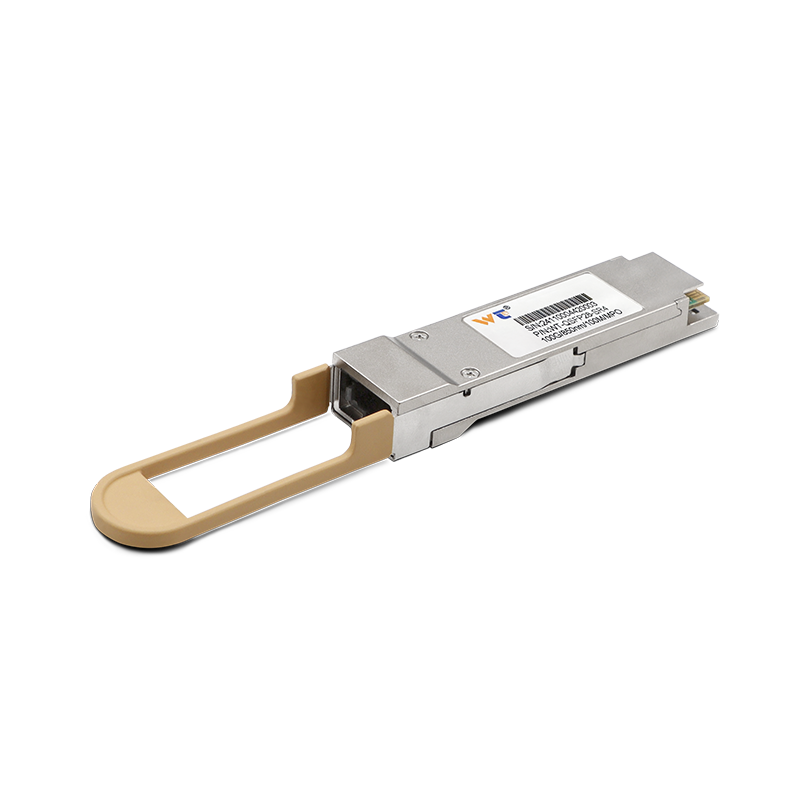

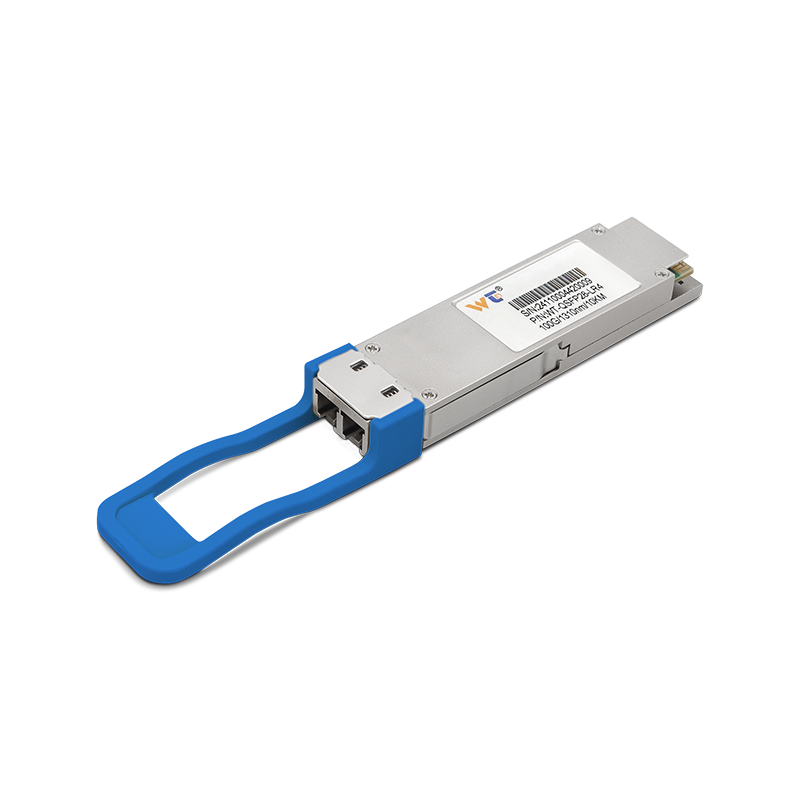

Diving deeper, there are various types of optical module technologies benefiting smart manufacturing. QSFP28 (Quad Small Form-factor Pluggable) modules lead the pack, providing robust performance for data centers. Their support of 100G Ethernet aligns perfectly with data-intensive applications. SFP28 (Small Form-factor Pluggable) modules also play a significant role, especially where space and power efficiency are vital. Additionally, PLC (Planar Lightwave Circuit)-based modules are gaining traction due to their ability to manage numerous channels effectively within a compact format. The continued innovation in these technologies will drive the smart manufacturing sector, enhancing the scalability and flexibility of applications like IoT devices and automation systems.

As we approach 2025, several networking scenarios will exemplify the implementation of these optical modules. For instance, a smart factory may deploy a mesh network powered by 100G optical modules, facilitating real-time monitoring of production lines. This setup allows for instantaneous data feedback and optimized decision-making processes. Furthermore, industries may implement AI-driven analytics alongside advanced fiber optics to enhance operational insight, resulting in decreased downtime and increased throughput. These use cases highlight how the convergence of optical technology and smart applications will revolutionize operational paradigms.

Our website offers a comprehensive range of optical module products, all subjected to rigorous quality testing to ensure they excel across varied application scenarios. Whether you require high-speed data transmission for complex automated processes or long-distance communication for inter-factory connectivity, our optical modules are engineered to meet and exceed your expectations. Every product is designed with meticulous attention to detail, ensuring that it delivers consistency and reliability in performance.

To summarize, as smart manufacturing gears up for 2025, the reliance on high-performance 100G optical modules will only intensify. These modules not only facilitate efficient communication but also drive innovations that redefine operational capabilities. By integrating cutting-edge optical technology into everyday practices, industries can maximize productivity while minimizing costs and latency. It’s clear: the future of manufacturing hinges on exceptional optical performance.