The integration of optical modules in smart manufacturing is set to revolutionize the industry by 2025. With the demand for high-speed data transmission and real-time communication skyrocketing, the role of advanced optical modules will be pivotal. As we move into an era of smart factories, these technologies will not only enhance productivity but also ensure seamless connectivity between systems.

In the optical module market, a significant trend is the adoption of 100G optical modules. These components are essential for handling the increasing data flow within smart manufacturing environments. A report shows that the global optical module market is projected to grow at a CAGR of 14.5% from 2020 to 2025. This growth is driven by the need for efficient data processing and the surge in IoT devices that require robust communication networks. Challenges such as latency reduction and interoperability across various platforms will compel manufacturers to invest in next-generation optical technologies.

| Technology | Function | Advantage |

|---|---|---|

| 100G QSFP28 | Supports up to 100 Gbps data rates | High-density interface for efficient data flow |

| 200G CFP2 | Enhanced bandwidth for data-intensive applications | Ideal for data centers and high-performance computing |

| 400G DR4 | Supports long distances while maintaining data integrity | Optimized for large-scale network environments |

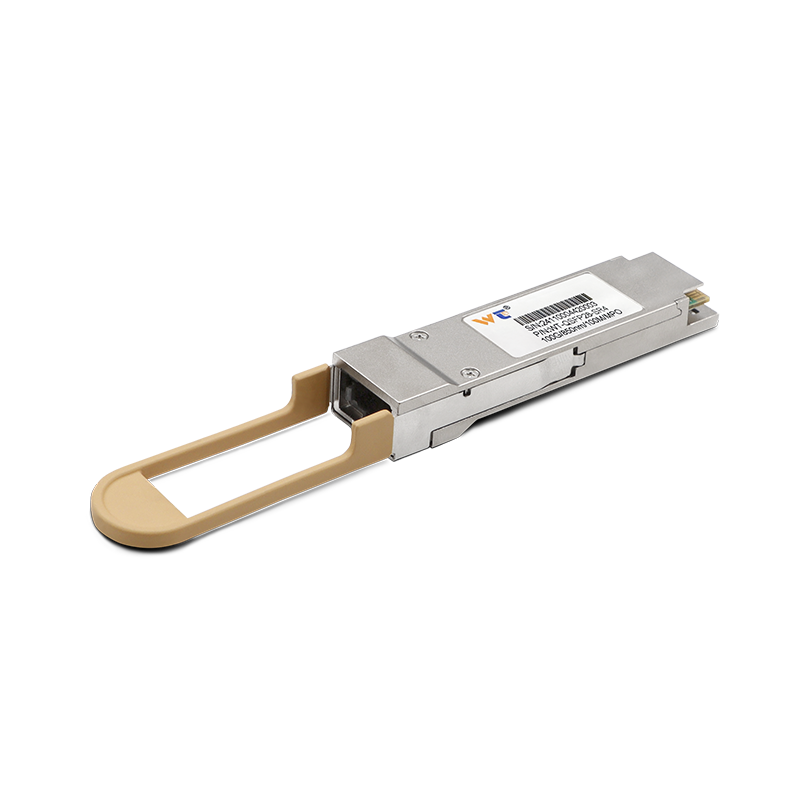

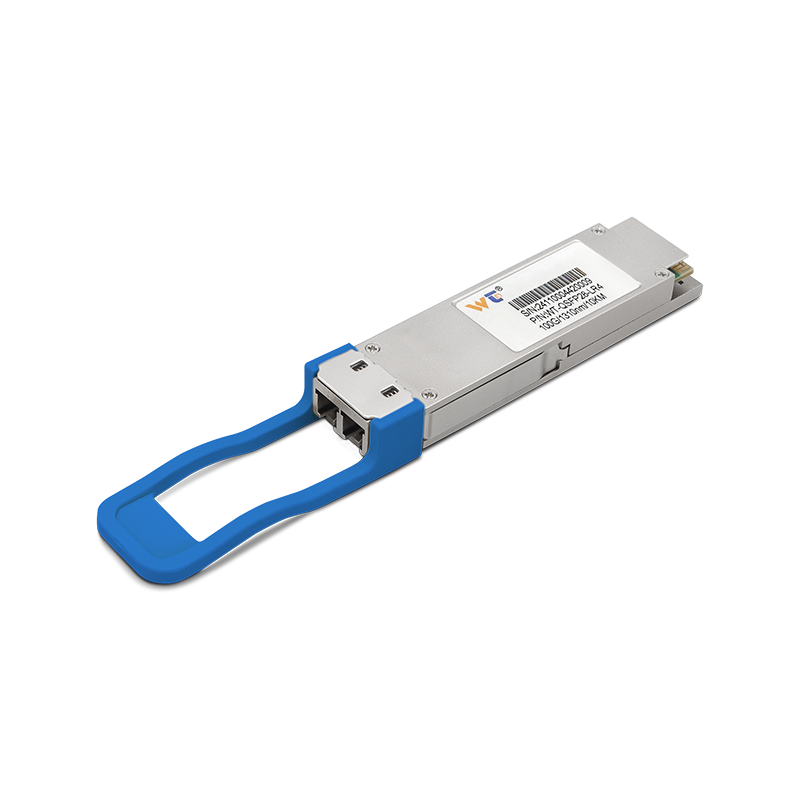

Three primary types of optical modules are gaining traction in the smart manufacturing sector: 100G QSFP28, 200G CFP2, and 400G DR4. Each type presents unique capabilities tailored for specific industrial applications. For instance, 100G QSFP28 modules are designed for high-density implementations, serving the needs of data centers for less than 100 meters. Conversely, 200G CFP2 modules cater to environments demanding extensive bandwidth, often found in telecommunications. The 400G DR4 modules, with their long-distance support, promise data integrity over greater spans, crucial for expansive manufacturing networks. Their ability to deliver both speed and performance empowers manufacturers to innovate while maintaining robust operational frameworks.

By 2025, we will witness various scenarios unfolding with these optical modules driving smart manufacturing networks. Envision an automated factory floor where machines, sensors, and operators communicate seamlessly. For instance, using 100G optical modules, a production line could relay data about equipment efficiency in real time, allowing immediate adjustments to optimize output. Further, a complete overhaul of upstream supply chains can be achieved through networked logistics. By employing 400G DR4 modules, manufacturers can enhance their communication infrastructure, enabling comprehensive tracking from supplier to assembly line.

At our website, we provide high-quality optical modules that undergo rigorous quality testing. Our products ensure exceptional performance in a variety of applications. Whether your needs include high-speed data transmission for real-time analytics or long-distance communication to connect multiple production units, our optical modules are engineered to excel in these environments. Each module is crafted to meet the demanding specifications required for modern industrial applications, giving you peace of mind in your investment.

To summarize, the integration of 100G optical modules coupled with smart scheduling systems in smart manufacturing brings unparalleled potential. As we approach 2025, the anticipated advancements in optical technology will drive the evolution of manufacturing processes, enhancing efficiency and productivity. With innovations paving the way for interconnected smart factories, embracing these technologies is essential for leading the future of manufacturing.