The integration of technology into various industries is rapidly evolving. By 2025, smart manufacturing systems will demand seamless communication and data transfer capabilities. This is where 100G optical modules will play a pivotal role, acting as the backbone of smart warehouse systems. As "friendly editors," we are excited to explore this dynamic intersection of technology and industry.

The market trend for optical modules is witnessing a significant shift. The demand for high-speed data transmission continues to surge, driven by the exponential growth of data in smart manufacturing. According to industry reports, the optical module market is expected to reach $25 billion by 2025, fueled by advancements in fiber optics and networking equipment. As smart warehouses become increasingly automated, the need for efficient and reliable communication solutions is paramount. Optical modules, especially those operating at 100G, are at the forefront, providing the necessary infrastructure to support high bandwidth needs. This technological evolution not only enhances operational efficiency but also supports the growth of IoT devices within the manufacturing ecosystem.

To better understand the role of optical modules, consider the table below that summarizes their key technologies and functions:

| Technology | Function |

|---|---|

| 100G Ethernet | Supports high-speed data transfer rates. |

| DWDM (Dense Wavelength Division Multiplexing) | Maximizes fiber capacity by enabling multiple signals through various wavelengths. |

| CWDM (Coarse Wavelength Division Multiplexing) | Reduces costs and complexity in networks while providing decent bandwidth. |

| Transceivers | Facilitates communication between various network types. |

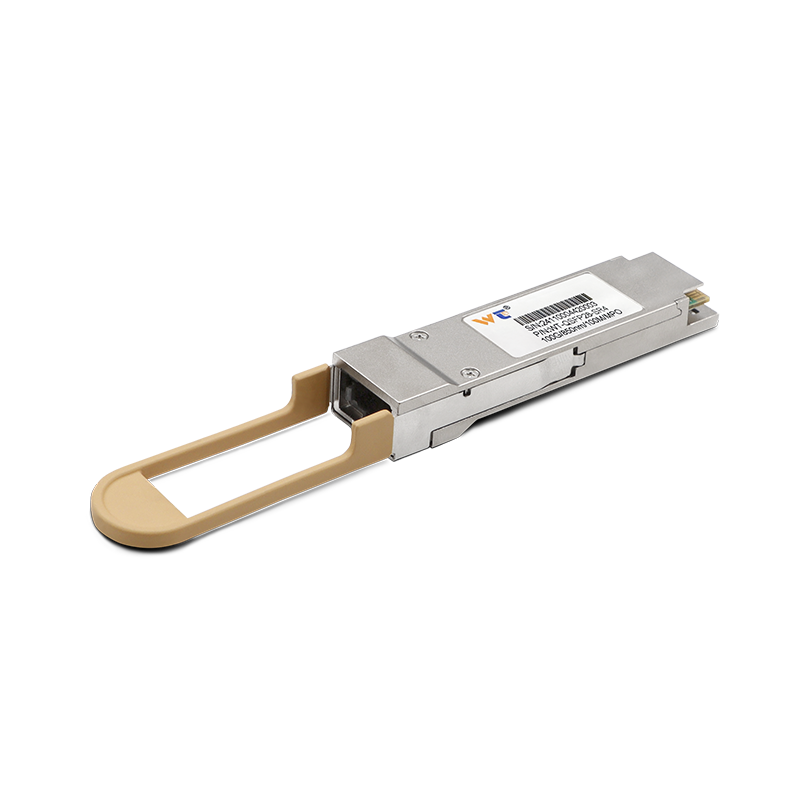

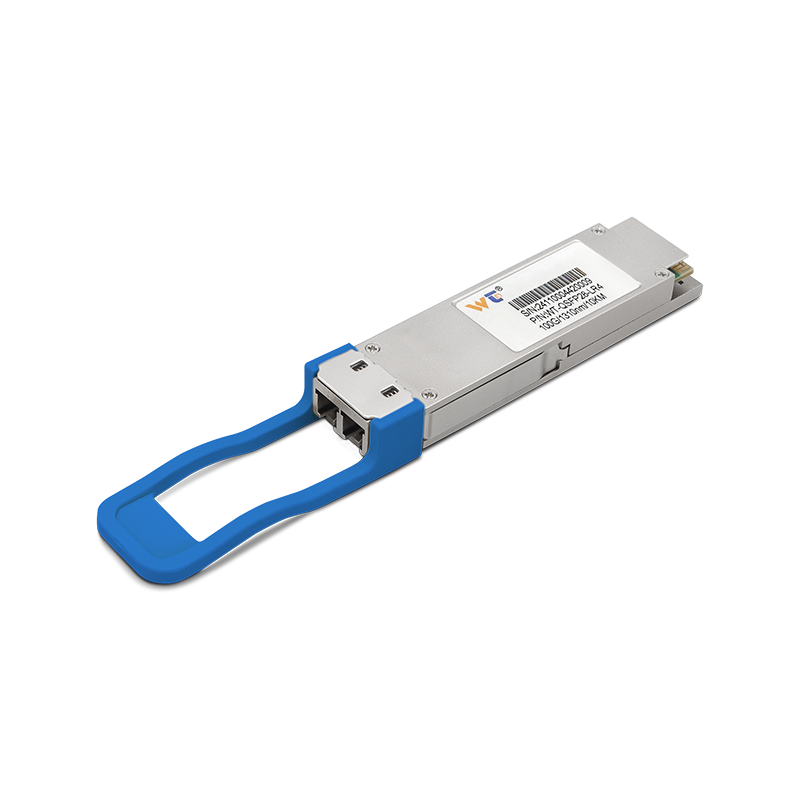

The types of 100G optical modules are diverse, each serving unique purposes within smart manufacturing. For example, the 100GBASE-SR4 module is designed for short-range applications, perfect for within the same data center. In contrast, the 100GBASE-LR4 is ideal for long-distance connections, offering reliable performance over distances up to 10 kilometers. Manufacturers are increasingly adopting these modules to effectively handle vast amounts of data, ensuring that their smart warehouse systems run smoothly and efficiently. Furthermore, the advancement of optical interconnect technologies is enhancing speed and reducing latency, making 100G modules an essential part of modern manufacturing infrastructures.

Looking ahead to 2025, we anticipate numerous practical applications of optical modules in smart warehouse networking. Imagine a scenario where IoT devices communicate seamlessly, powered by 100G optical interconnects. This setup will enable real-time inventory tracking, automated order fulfillment, and instant data analysis. Additionally, predictive maintenance efforts will be supported by these robust networks, leading to significant cost savings and increased productivity. Case studies have shown that companies implementing such technologies see productivity improvements of up to 30%. The transition to 100G technology is not merely about speed; it's about transforming the entire manufacturing process.

At our website, we offer a range of optical module products that have undergone stringent quality testing. Each module is designed to excel in various applications, ensuring performance in high-speed data transmission or long-distance communication. Whether you require enhanced connectivity within a smart warehouse or reliable data transfer across multiple locations, our 100G optical modules are tailor-made to meet your specific demands. We are committed to delivering solutions that empower businesses to thrive in the fast-evolving landscape of smart manufacturing.

In conclusion, the integration of 100G optical modules with smart warehouse systems is set to redefine the future of manufacturing. As we move towards 2025, the synergy between optical technology and smart solutions will unlock new possibilities, enhancing efficiency, reliability, and productivity. Embracing these advancements will not only keep businesses competitive but will also pave the way for innovative manufacturing practices. With the right tools and technology, the future of manufacturing is indeed bright.