The advancement of technology in smart manufacturing is creating an ever-increasing demand for high-speed communication systems. By 2025, industries will rely heavily on 100G optical modules, enabling real-time data transfer and control that boosts productivity and efficiency. As the landscape evolves, the integration of these modules in manufacturing will transform operational processes, making them more agile and responsive.

The optical module market is undergoing significant evolution, driven by the need for faster communication and seamless connectivity. In smart manufacturing, optical modules serve as the backbone of data transmission networks. These devices convert electrical signals into optical signals, enabling high bandwidth at minimal latency. Industry reports show that the global optical module market is expected to reach $10 billion by 2025, largely influenced by the surge in IoT devices and increasing demand for cloud services. The integration of 100G optical modules will further propel industries toward smarter manufacturing, facilitating faster decision-making processes and efficient resource allocation.

| Technology | Description | Application |

|---|---|---|

| 100G Transceiver | Transmits and receives data at speeds of 100 gigabits per second. | High-speed communication. |

| CWDM/DWDM Modules | Allows multiple signals to be transmitted simultaneously over the same fiber. | Long-distance communication. |

| PAM4 Encoding | Increases data capacity by encoding four bits per symbol, enhancing efficiency. | Data centers and backhaul links. |

The types of optical modules essential for smart manufacturing include 100G transceivers, CWDM/DWDM modules, and PAM4 encoding technologies. The transceiver's capability to manage high data throughput—at speeds reaching up to 100 Gbps—enables the effective handling of real-time data processing. Meanwhile, CWDM and DWDM modules support the transmission of multiple data streams simultaneously, crucial for modern automated workflows. Additionally, PAM4 encoding significantly enhances transmission capacity, allowing for substantial reductions in infrastructure costs by utilizing existing fiber networks. Integrating these technologies ensures that manufacturing systems are capable of withstanding increasing data demands.

As we look towards 2025, network configurations utilizing 100G optical modules will become standard. Scenarios may include smart factories where real-time control of machinery is paramount. For instance, in an automated assembly line, sensors relay data back to a central processing unit via optical modules, facilitating immediate responses to production inefficiencies. Companies implementing this technology can expect enhancements in their operational capabilities, including reduced downtimes and increased throughput.

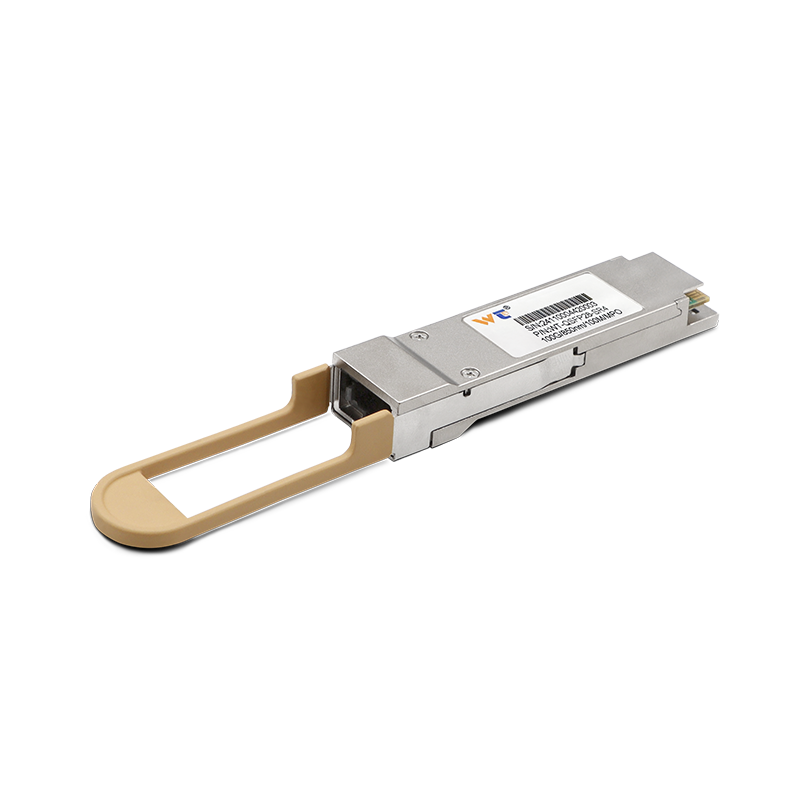

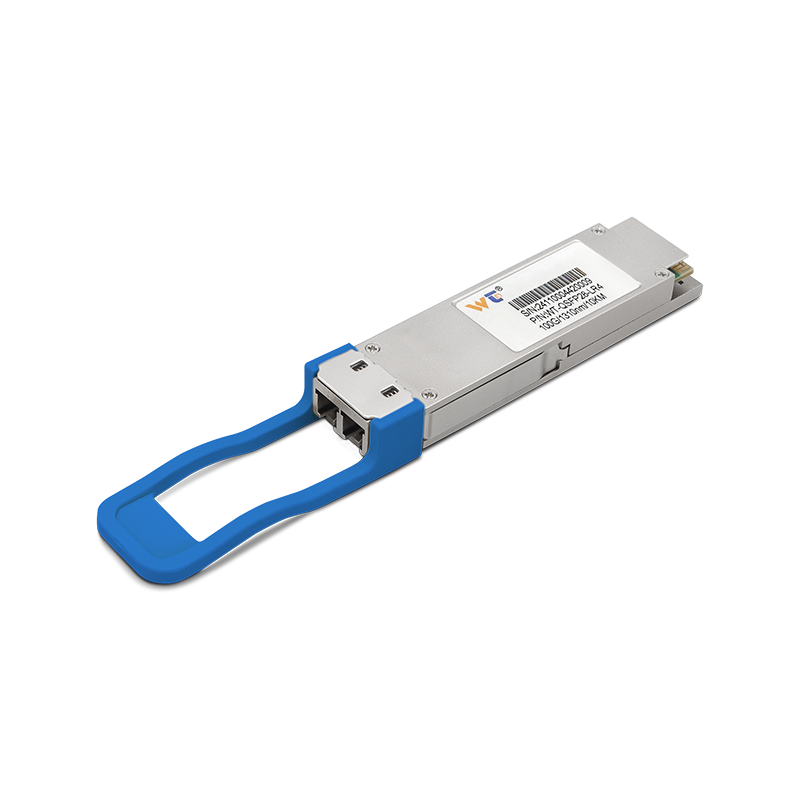

We take pride in offering high-quality optical module products on our website, all undergoing rigorous quality testing to ensure outstanding performance across various application scenarios. Whether you need cutting-edge solutions for high-speed data transmission or reliable options for long-distance communication, our optical modules are engineered to meet your needs effectively. With our commitment to quality, you can trust that your investment in our products will yield significant benefits in your smart manufacturing processes.

In conclusion, the rapid advancements in 100G optical modules are set to redefine the smart manufacturing landscape. As industries prepare for the demands of 2025, the integration of these technologies will be essential in achieving greater operational efficiencies and enhancing productivity. With robust solutions available, companies should leverage these advancements to stay ahead in an increasingly competitive market.