The smart manufacturing landscape is evolving rapidly, and by 2025, we will witness a significant transformation in how industrial robots communicate with 100G optical modules. The need for high-speed and reliable data transmission systems is paramount. This shift is driven by the demands of real-time processing, automation, and increased operational efficiency in manufacturing environments.

Optical modules have emerged as a critical component in this revolution. These small, yet powerful devices are designed to transmit data over fiber optic cables at incredible speeds — up to 100 Gbps. As industries move towards automation, the demand for seamless communication between machinery and data systems grows. The integration of optical modules enhances data transfer capabilities, providing robust connections that ensure downtime is minimized and productivity is maximized. With an increasing focus on Industry 4.0 technologies, the market for optical modules is projected to expand significantly, driven by innovations in both hardware and software.

| Technology/Characteristics | Function |

|---|---|

| Form Factors | SFP, SFP+, QSFP, CFP |

| Bandwidth | Up to 100 Gbps |

| Distance | From meters to kilometers |

| Wavelengths | 850nm, 1310nm, 1550nm |

| Applications | Data centers, telecom, manufacturing |

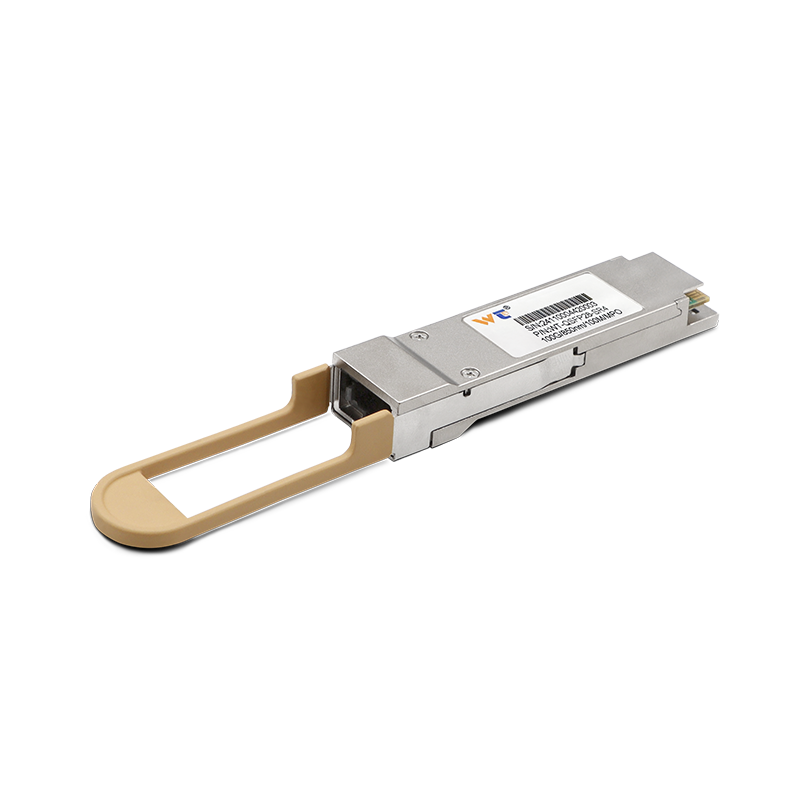

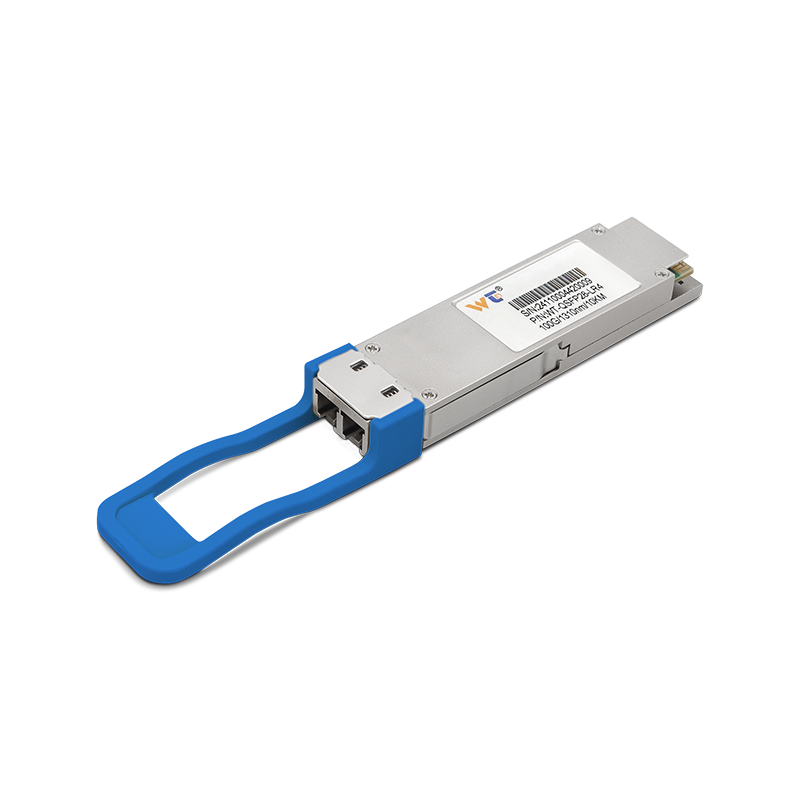

There are various types of optical modules that cater to the diverse needs of the manufacturing sector. SFP (Small Form-factor Pluggable) modules are popular for their versatility and compact design, suitable for many applications. SFP+ modules, with improved bandwidth capabilities, support data transmission up to 10 Gbps. As demands increase, QSFP (Quad Small Form-factor Pluggable) modules stand out, enabling quadruple data rates and offering up to 100 Gbps speeds. These advancements ensure manufacturers can synchronize their robotic systems efficiently, enhancing overall productivity and reducing latency.

Looking ahead to 2025, the landscape of optical modules and network scenarios will be defined by advanced integration. Consider a scenario where a smart factory utilizes 100G optical modules connected to a network of industrial robots. These robots, equipped with sensors and AI algorithms, communicate in real time via optical links. This configuration allows for rapid data processing from the AI systems, ensuring immediate response to conveyor movements, product quality assessments, and resource allocation. Such an architecture not only enhances efficiency but allows factories to adapt dynamically to changing production needs.

Our website offers optical modules that have undergone rigorous quality testing, ensuring they perform exceptionally in various application scenarios. Whether for high-speed data transmission or long-distance communication, our optical modules meet stringent industry standards. We understand the critical nature of reliable connectivity in smart manufacturing, and our products are designed to ensure operational excellence. With options that support various bandwidths and distances, we provide solutions tailored to specific needs of manufacturers looking to enhance their automation processes.

In conclusion, the ongoing integration of 100G optical modules in smart manufacturing signifies a pivotal shift toward increased efficiency and automation. As we approach 2025, the convergence of advanced optical technologies and industrial robotics will reshape how factories operate. With the unparalleled capabilities of our optical modules, manufacturers can confidently embrace the future of automation and ensure their systems are primed for success in an increasingly competitive marketplace.