The field of optical modules is rapidly evolving, particularly as we edge toward 2025. As a dedicated editor focused on technology and science communication, it’s essential to highlight how the increasing demand for high-speed data transmission and long-distance communication technology drives advancements in optical module products. By 2025, the integration of automated testing technologies in smart manufacturing will significantly enhance the reliability and performance of these modules, catering to a broad range of industry needs.

Optical modules, which enable the transmission of data over fiber-optic networks, represent a crucial component in telecommunications and data centers. The market for optical modules is expected to witness important growth, driven by demands for 100G and higher-speed connections. Studies indicate that the global optical module market was valued at approximately $3 billion in 2020 and is projected to reach around $8 billion by 2025. This growth is primarily attributed to the increasing reliance on cloud computing, IoT, and 5G technologies, demanding robust data transmission capabilities.

| Optical Module Technology | Function |

|---|---|

| Transceivers | Convert electrical signals to optical signals and vice versa |

| Amplifiers | Boost the strength of the optical signal for long distances |

| Wavelength Division Multiplexing (WDM) | Allows multiple signals over a single fiber to maximize bandwidth |

| Passive Optical Networks (PON) | Provides fiber-to-the-home services by enabling multiple connections from a single fiber strand |

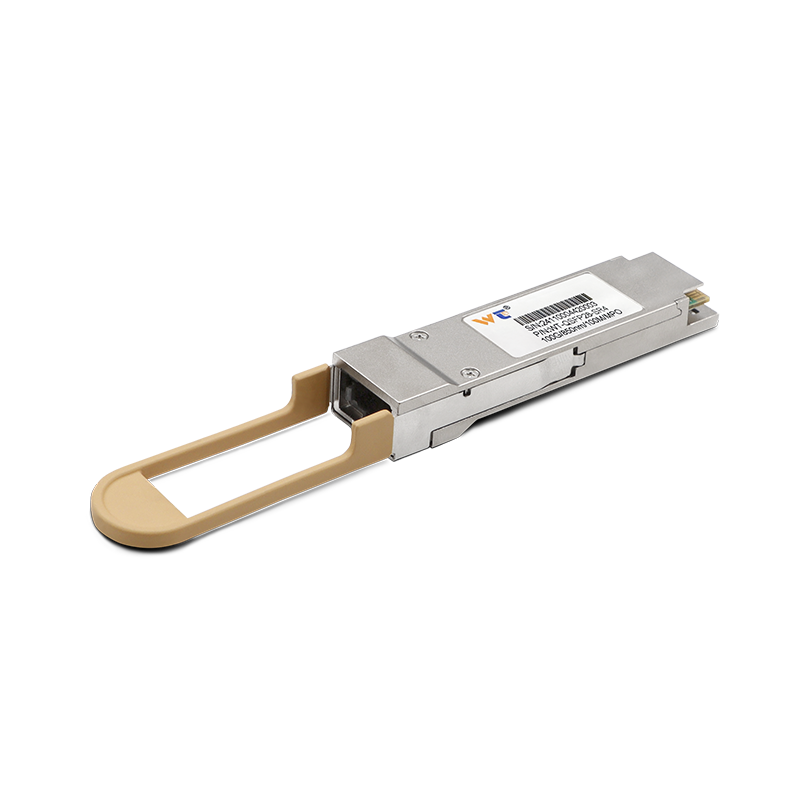

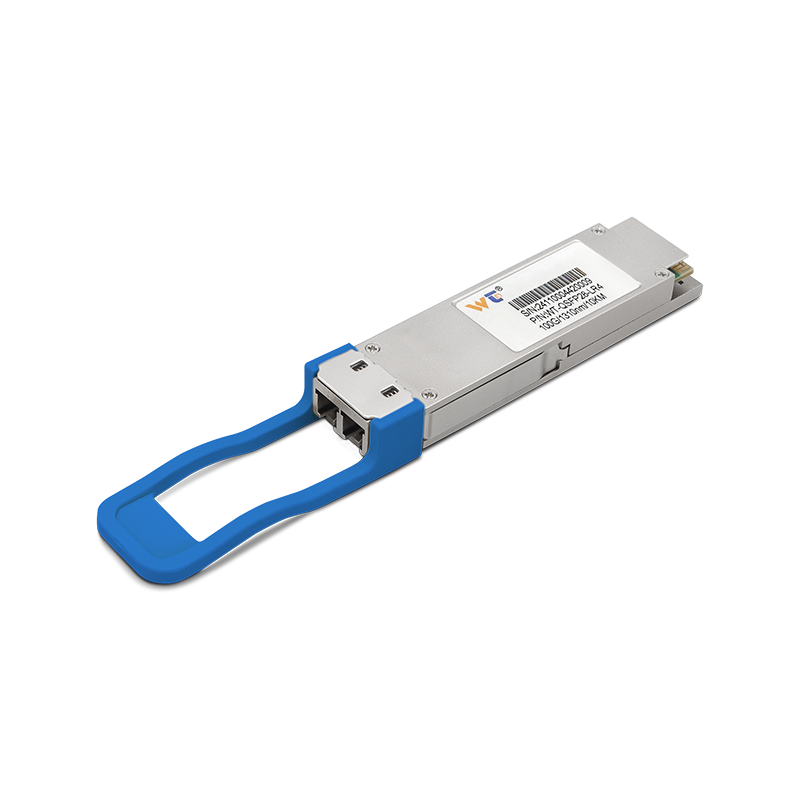

There are several types of optical module technologies, each serving critical functions in modern network infrastructure. SFP (Small Form-factor Pluggable) and QSFP (Quad Small Form-factor Pluggable) are among the most common types used in data centers. SFP modules support data rates up to 1G, while QSFP can handle up to 100G, facilitating significantly higher throughput levels. Additionally, coherent detection technologies further enhance the performance of long-distance communication by enabling the transmission of multiple channels over the same fiber optic infrastructure. By providing reliable signal integrity and increased bandwidth, these technologies form the backbone of the next-gen optical network systems.

By 2025, the implementation of optical modules in real-world applications will become increasingly sophisticated. Smart manufacturing will drive the need for high-capacity bandwidth to support complex data analyses and real-time monitoring. Advanced networks, employing WDM technology, will enable factories to manage data-driven machinery more efficiently. Scenario-based networking, where multiple processes are seamlessly interlinked via optical modules, will exemplify effective industrial operations. For instance, a factory using optical technologies can coordinate between various production lines, optimizing performance with minimal latency and downtime.

At our website, we offer optical module products that undergo strict quality testing. Our commitment to excellence ensures that these modules shine in diverse applications. Whether it’s for high-speed data transmission to support giant data centers or long-distance communication for telecom infrastructure, our optical modules are designed to meet demanding industry standards. We understand that performance, reliability, and durability are non-negotiable factors in your operational framework.

In summary, the advancements in optical modules and their applications in smart manufacturing are poised to reshape the telecommunications landscape by 2025. As we look forward to these developments, it is clear that automated testing technologies will play a vital role in ensuring quality and performance. Through enhanced optical connectivity and innovative networking solutions, we stand ready to meet the requirements of an increasingly data-driven world.